-40%

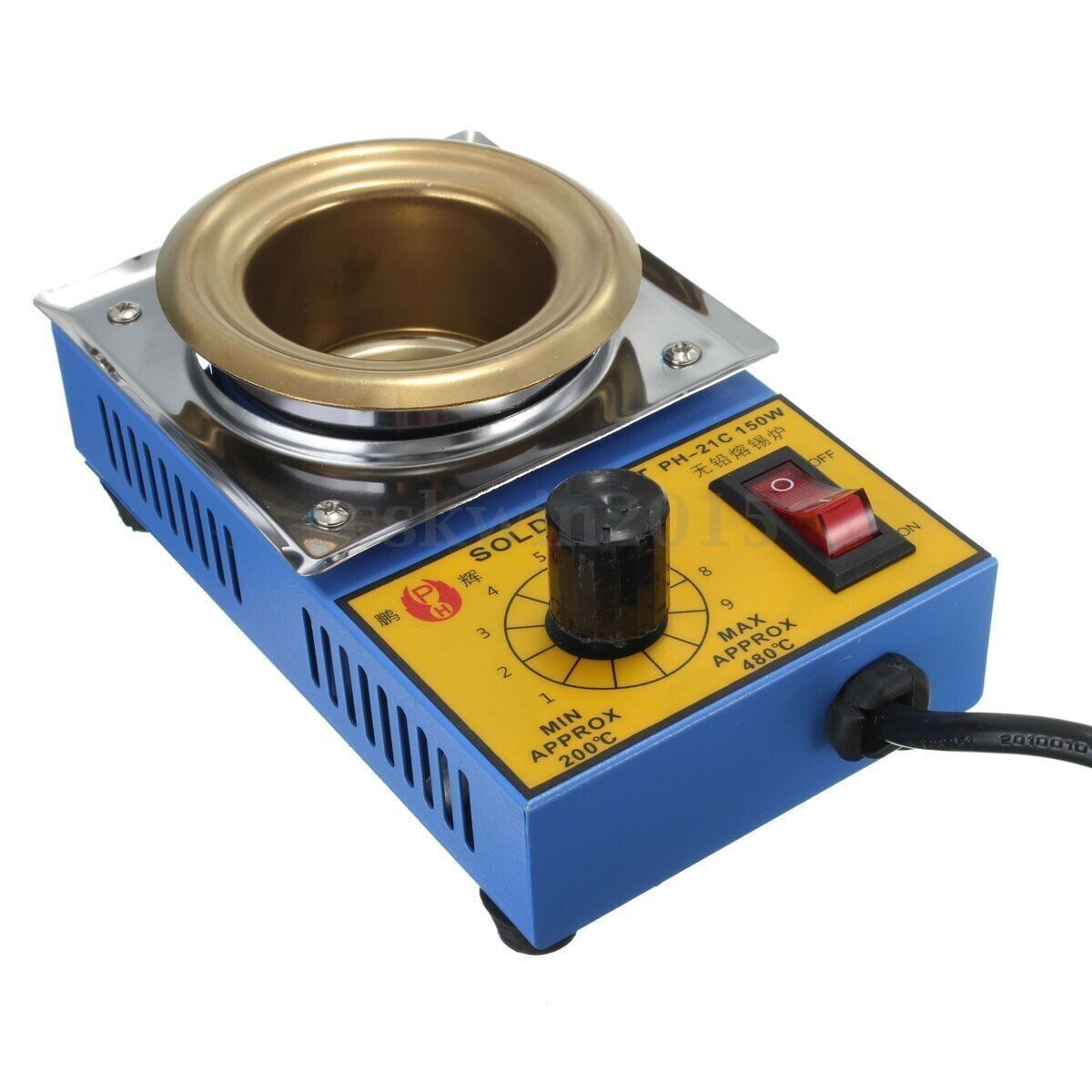

Solder Pot Soldering Desoldering Bath Stainless Steel Plate 150W 220V 200-480°C

$ 23.72

- Description

- Size Guide

Description

Features:Model: 21C

Power:150W

Temperature range:200-480°C

Melted solder capacity: 500g

Tin pot diameter(mm): 50mm

Material: Stainless steel

Input voltage: AC220v 50Hz

Product size: length:150mm

width:87mm

Wire length:840mm

Specifications;

1 Electronic temperature regulating plates, some of the imported components production.

2 Tin furnace is made of imported stainless steel plate, according to regulate the temperature, automatic constant temperature.

3 Easy to use, easy maintenance, good heat effect, melting tin fast.

4 The titanium alloy solder bath and other heavy duty compents offer greater durability.

5 High power heater,quickly melten the lead-free tin bar.

Welding method:

1 Firstly,you should put the tin bar into the furnace to melt (melting point of Pb SN is about 250 DEG C, lead-free solder melting point of 300 DEG C or so, slug melting 328 DEG C or so)

2 Secondly,put the flux in another container (the welding foot to touch);

3 Thirdly,when you are welding,you should put the welding feet on the flux to dip, then put into the dip soldering tin stove.

4 Lastly,after the temperature of welding becomes cooling,it means the welding is finish.

Package Included:

1 pc lead-free solder pot

1 Electronic temperature regulating plates, some of the imported components production. 2 Tin furnace is made of imported stainless steel plate, according to regulate the temperature, automatic constant temperature. 3 Easy to use, easy maintenance, good heat effect, melting tin fast. 4 The titanium alloy solder bath and other heavy duty compents offer greater durability. 1 Firstly,you should put the tin bar into the furnace to melt (melting point of Pb SN is about 250 DEG C, lead-free solder melting point of 300 DEG C or so, slug melting 328 DEG C or so) 2 Secondly,put the flux in another container (the welding foot to touch); 3 Thirdly,when you are welding,you should put the welding feet on the flux to dip, then put into the dip soldering tin stove. 4 Lastly,after the temperature of weldi